D-cant

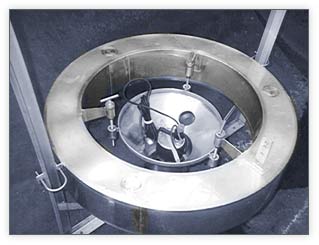

The D-Cant range of clarified liquid decanters typically consist of a submerged bellmouth or rectangular weir that is supported by floats and discharges via a flexible pipe.

The weir is designed and installed to remove clarified liquid from the surface of a tank or basin without disturbing deeper layers where solids may be concentrated.

D-Cant: The D-Cant range enables the removal of clarified liquid without solids entrainment.

This enables the removal of clarified liquid without solids entrainment and is particularly applicable to batch or sequenced plant operations.

Conversely, the D-Cant can, in certain applications be applied as a surface scum removal device with minor design alterations.

History and Design

In recent years, the rise in popularity of batching or sequencing treatment plant designs has led to a number of complex and expensive clarified liquid decanting equipment options.

In response to requests from consultants and end-users, PCPL designed a range of simple floating decanters to perform the requisite duty in a simple and low cost fashion.

Hundreds of these units are now successfully installed. These units handle applications from very low flows up to 400 litres per second in a single unit, and much larger flows using multiple unit installations.

Flexibility of Design and Control

The D-Cant can be supplied as either a gravity decanter, typically activated by an actuated or manual valve arrangement, or as a positively pumped decanter fitted with either a submersible or surface mounted pump.

Larger positively pumped D-Cants can be fitted with variable speed drives to enable fine tuning and better control of discharge volumes.

Discharge operations can be simply meshed into existing or new plant control logic.

Larger models can be fitted with walkways and handrails and can be fitted with bridge access from side of basin if required.

Surface Scum Exclusion

The D-Cant weir is typically protected from the surface of the operating basin via a scum exclusion skirt all around.

Variable Weir Depth

Depth of weir is adjustable via a series of special threaded rod supports attached to the flotation frame and can be operated simply.

Maintenance

As the D-Cant has few or no moving parts, it is an extremely simple piece of equipment to set up and maintain compared to other liquid decanting technologies.

High quality materials of construction ensure very long equipment life span.

Custom Design

Although PCPL D-Cant units fit within basic duty and size ranges, experience has shown that most liquid decanting (and scum removal) applications are each in some way different and require a degree of customisation.

Factors that may effect any particular design are the weir loading rate, solids loading of the basis liquid, level of water fluctuation, decanted volume range variation etc.

Australian Made - World Class

The entire D-Cant range is designed and manufactured wholly within Australia with local parts support – and has been exported all over the world.